Common failure of the 615 Engine

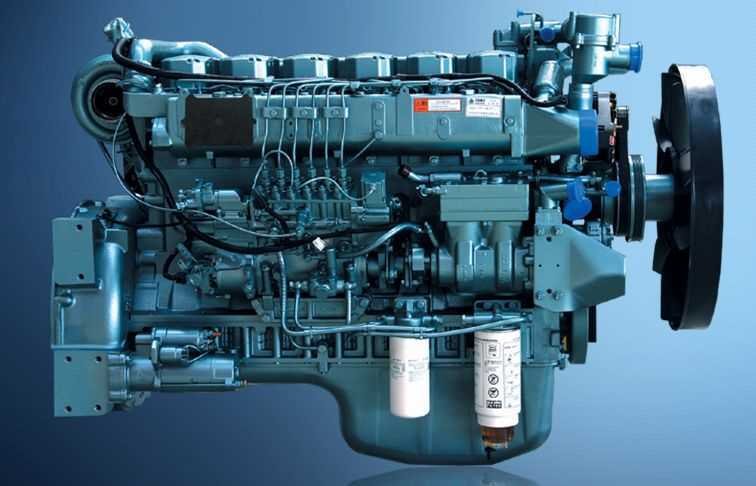

Engine Introduction

615 is the main installed engine of Sinotruk brand Xiahowo HOHOO, the mainstream model of Steyr. There are various reasons for the failure of D615 diesel engine. One reason will make the diesel engine show a variety of abnormal phenomena, and one fault phenomenon may be caused by a variety of reasons.

The inspection and judgment of the fault usually use to see, hear, touch, smell and other methods, from simple to complex, from the surface to the inside.When troubleshooting the fault, the fault nature should be judged according to the fault characteristics.

Comprehensive analysis of various phenomena to find out the relationship between them, can not immediately identify the cause of the fault, in the premise of determining that no major accident will occur, the diesel engine can be operated at low speed observation analysis, find out the cause.

Failure analysis

As engine production increases, all truck engine manufacturers are fighting for a share of the sluggish market.As for after-sales service, it is generally more empty than actual service, turning the product chain into a large warehouse of spare parts.

Based on this, many truck users believe that it is right to replace parts when something goes wrong, therefore, replacing parts blindly can cause many problems.

For the WD 615 engine, the main oil line supplies not only the crankshaft but also the camshaft.The oil first passes through the oil cooler and filter, and then through a different route.

In this case, the wear is caused by impurities in the oil circuit.In general, the WD 615 engine oil filter has a relief valve. Once the filter is clogged with impurities, the relief valve will open to allow the oil passage to proceed smoothly, so that impurities can enter the oil passage.It’s a time bomb.

Therefore, when the engine first goes to the workshop, only the damaged parts are replaced and nothing else is done.But the core treatment is to change the filter, change the oil, clean all the oil lines, and then replace the broken parts.

For trucks working in construction, the time to change the filters depends not on the distance traveled but on the time spent working.If there are many steep hills, add dual pumps if possible to avoid a lack of oil pressure in the oil line.